After the discussion about types of resins, this time Watermart will discuss the differences between cation and anion resins. Cation resins are materials used to exchange cation ions in water, such as calcium and magnesium. These ions cause water hardness that can interfere with various industrial processes and daily use.

Cation resins play an important role in water softening systems, which reduce water hardness by replacing calcium and magnesium ions with lighter ions, such as sodium. In contrast, anion resins are responsible for exchanging anion ions, such as chloride and sulfate, which can cause corrosion, taste, and other problems in water.

What is Cation Resin?

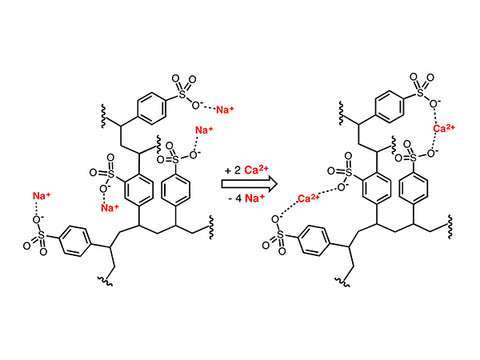

Cation resin is a type of ion exchange resin used to remove positive ions (cations) from water. These ions include heavy metals such as lead and copper, as well as more common cations such as calcium and magnesium, which are often responsible for water hardness. These resins are usually made of polystyrene sulfonate which serves as a base to capture those positive ions, replacing them with sodium or hydrogen ions.

In addition, cation resins can also be used in a variety of other applications, such as water treatment for food and beverage production, as well as in industrial wastewater treatment to reduce heavy metal contamination. Their effectiveness in handling a wide range of cations makes cation resins an essential component in modern water treatment systems.

What is Anion Resin?

In contrast to cation resins, anion resins are designed to remove negative ions (anions) from water. These include fluoride, chloride, and sulfate. Anion resins typically utilize a quaternary amine base that is able to attract and bind negative ions, replacing them with hydroxide or chloride ions, depending on the type and needs of the water treatment being performed.

Anion machines are also effective in lowering the conductivity level of water, making them essential for applications that require high levels of water purity, such as in semiconductor manufacturing and pharmaceutical processes. Their success in reducing these contaminants makes anion resins a key component in water demineralization and deionization systems.

Key Differences Between Cation and Anion Resins

Key Differences Between Cation and Anion Resins

In water treatment, an understanding of the differences between cation and anion resins is critical to optimizing the process and selecting the right technology. Although these two types of resins function as ion exchangers, they have significant differences in their mechanism of action, chemical composition, and application of use. Here is an explanation of the key differences between cation and anion resins:

-

Ion Exchange Function: Cation resins exchange with positive ions, such as sodium, calcium, and magnesium, which are often responsible for water hardness. Meanwhile, anion resins exchange with negative ions, including sulfate, nitrate, and chloride, which are important to control for better water quality.

-

Chemical Structure: Cation resins are made of sulfonic acid or similar, which gives them the ability to attract positive ions from the solution. In contrast, anion resins are made of quaternary bases, which are effective in attracting and binding negative ions.

-

Use Applications: Cation resins are often used in water softening processes to reduce hardness caused by calcium and magnesium. On the other hand, anion resins are used in demineralization or specific contaminant removal, which involves the reduction of negative ions from water for applications that require high levels of purity, such as in the pharmaceutical and electronics industries.

Both of these resin types are vital in various water treatment applications, suggesting that the selection of the right resin type can greatly affect the efficiency and end result of the water treatment process.

Uses in the Water Treatment Industry

In the water treatment industry, a combination of these two resin types is often required to achieve the desired water quality. For example, in deionization systems, cation and anion resins are used together to remove nearly all ions from water, resulting in highly purified water, often used in laboratories and industrial processes.

In addition, these resins are also vital in the reverse osmosis pre-treatment process to prevent membrane fouling that can damage the system. Cation and anion resins are also used in power generation, where highly controlled water quality is critical to avoid corrosion and mineral buildup in boilers and turbines. Their effectiveness in reducing total dissolved solids (TDS) makes these resins a top choice for industries that require high standards of water cleanliness and purity, such as in the manufacture of beverages and pharmaceutical products.

Choosing the right resin, be it cation or anion, depends on the specific water treatment needs at hand. Watermart, as a distributor of water treatment equipment, provides a range of solutions to help meet these various needs by providing high quality products that suit the water treatment needs in Indonesia. The use of the right resin not only ensures optimal water quality but also improves operational efficiency and reduces maintenance costs.

Understanding the difference between cation and anion resins is not only important for water treatment engineers and specialists, but also for those involved in the distribution and supply of water treatment equipment. This information helps in selecting the right equipment for each specific water treatment need, which in turn increases the efficiency and effectiveness of the water treatment system.

If you need more information regarding cation and anion resins or require consultation for your water treatment needs, feel free to contact Watermart via Whatsapp or e-mail. We are ready to assist you with the right solution tailored to your specific needs.

Contact us today for consultation and quality products from Watermart.

.png?width=50&height=50&name=Logo_Watermart_Perkasa-removebg-preview%20(1).png)