How to Choose Activated Carbon for Your Water Treatment System

In the search for solutions to cleaner and healthier water, it is important to learn more about activated carbon.

This material, also known as activated carbon, plays a vital role in eliminating various contaminants from water, including chemicals, odors, and colors, making it an essential component in many water treatment systems. The uniqueness of activated carbon lies in its microporous structure, which provides a very large surface area in a relatively small volume, making it a highly efficient medium for contaminant adsorption.

By choosing the right activated carbon, you not only improve the quality of water consumed but also make an important contribution to the health and well-being of the surrounding environment. This selection process requires a good understanding of the properties of the water to be treated and the technical specifications of the activated carbon, to suit the specific needs of your water treatment system.

Understanding Activated Carbon and Its Uses

The activation process performed on activated carbon not only increases its effectiveness in absorbing contaminants but also expands its range of applications. Besides being used in drinking water treatment systems, activated carbon also plays an important role in industrial waste treatment, aquarium water treatment, as well as various air filtration applications.

The activation process creates a unique pore structure, which allows activated carbon to capture a wide range of contaminant molecules, from very small to larger. This includes the ability to remove chlorine, pesticides, herbicides, and pharmaceutical residues, making it a highly effective solution for improving water and air quality. The use of activated carbon has become standard in many water and air treatment protocols due to its incredible ability to improve the quality of our environment.

Why Choose Activated Carbon?

The decision to use activated carbon in water treatment systems is based not only on its extensive capabilities in contaminant removal, but also on its flexibility in various treatment scenarios. Activated carbon can be integrated into small-scale to large-scale water treatment systems, ranging from domestic use in households to industrial applications requiring large volumes of water treatment. This allows for customized use according to specific needs, be it for drinking water purification, wastewater treatment, or even in brewing and food processes, where the quality of the water largely determines the final quality of the product.

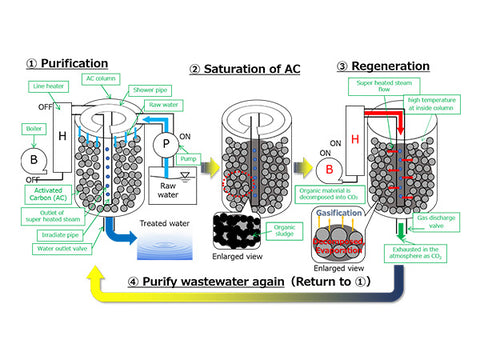

In addition, the use of activated carbon also offers advantages in terms of sustainability and economy. It can be regenerated and reused over multiple treatment cycles, reducing the need for constant material replacement and offering a more environmentally friendly solution. This regeneration process allows for operational cost savings and waste reduction, making activated carbon a smart choice not only from a technical aspect of water treatment but also from environmental and economic considerations.

Factors to Consider When Choosing Activated Carbon

In choosing the right activated carbon for your water treatment system, an in-depth understanding of the characteristics and specific applications of each carbon type is essential. The following is a further explanation of the key points already mentioned:

-

Types of Activated Carbon

-

Granular Activated Carbon (GAC)

-

The advantages of GAC lie not only in its effectiveness in removing contaminants, but also in the ease with which it can be integrated into different types of water treatment systems. GAC is ideal for use in household water filters, industrial water treatment systems, and drinking water treatment facilities. It allows for consistent water flow and minimal resistance, which is critical for long-term operation.

-

GAC maintenance is relatively simple as its larger granules facilitate backwashing and regeneration, minimizing downtime and maximizing operational efficiency.

-

-

Powdered Activated Carbon (PAC)

-

PAC is highly effective in addressing specific pollutants, such as halogenated organic compounds and micro-contaminants that GAC has difficulty removing. These characteristics make PACs the right choice for applications that require the treatment of specific contaminants with a high degree of precision, such as in industrial wastewater treatment or water purification for specific processes.

-

PAC applications require precise dosing and are often followed by an additional filtration process to remove PAC residuals from the treated water, guaranteeing exceptional final water quality.

-

-

-

Pore Size and Surface Area

-

Thermal or chemical activation used in the manufacture of activated carbon increases the surface area and pore volume, which are critical in determining adsorption effectiveness. Materials with larger surface areas have more active sites to capture contaminants, which significantly improves water filtration performance.

-

Customized pore sizes allow specific targeting of contaminants, from large molecules such as bacteria and protozoa, to small organic molecules and micropollutants, offering flexibility in water treatment system design.

-

-

Raw Material Source and Quality

-

Qualified raw materials not only affect the adsorption effectiveness but also the stability and safety of long-term use of activated carbon. For example, activated carbon derived from coconut shells is often considered to have smaller and more uniform pores, well suited for adsorption of volatile organic contaminants.

-

Choosing a product from a reputable distributor ensures that the activated carbon you use is not only effective but also safe and free from contaminants on its own. Trusted distributors often provide full documentation regarding the origin and manufacturing process of their products, providing peace of mind regarding quality and reliability.

-

A comprehensive look at these factors will guide you in selecting the most suitable activated carbon, ensuring your water treatment system operates at maximum efficiency and produces clean water that meets or even exceeds expected quality standards.

How to Use and Maintain Activated Carbon

To maximize the performance and extend the lifespan of activated carbon in a water treatment system, implementing proper use and maintenance practices is crucial. The following is a more detailed explanation and some additional tips that can help in the management of activated carbon:

-

Regeneration and Replacement

-

Performance Monitoring: Regular monitoring of the water treatment system performance will help determine the appropriate time for carbon regeneration or replacement. Indicators such as a decrease in output water quality or an increase in filtration time can be signs that the carbon is saturated and needs to be regenerated or replaced.

-

Regeneration Process: Some types of activated carbon can be regenerated by heating or the use of certain chemicals to remove adsorbed contaminants. This process should be done carefully according to the manufacturer's specifications to ensure the effectiveness and safety of the carbon.

-

-

Water Flow Management

-

Optimal Flow Management:Optimizing water flow through the activated carbon media is key to ensuring efficient contact between water and carbon. Optimal flow regulation allows sufficient contact time for the carbon to adsorb contaminants, without causing channeling or bypassing that can reduce filtration effectiveness.

-

Adjustments Based on Contaminant Load: Water flow and contact time with activated carbon should be adjusted based on the contaminant load encountered. Water with high contaminants may require slower flow for optimal adsorption effectiveness, while water with lower contaminants can be treated with faster flow without compromising filtration quality.

-

-

Current Maintenance

-

Inspection and Cleaning:Performing regular inspections and cleaning the container or media where the activated carbon is stored can prevent the accumulation of sediment or other obstructions that can reduce the effectiveness of the filtration.

-

Water Quality Testing: Periodically perform output water quality testing to ensure that the activated carbon is still functioning properly. This testing can be helpful in monitoring when to regenerate or replace.

-

Applying these principles of use and maintenance will ensure that the activated carbon in your water treatment system functions optimally, producing clean and safe water for use or consumption. Always consult the manufacturer or distributor for specific recommendations regarding the product you are using, as the characteristics and maintenance needs of each product may vary.

In facing the challenge of providing safe and healthy clean water, choosing the right activated carbon is a critical step that cannot be ignored. Every element, from carbon type to raw material quality, plays a vital role in determining the effectiveness of your water treatment system. Through an in-depth understanding of your specific application characteristics and needs, as well as the implementation of proper maintenance practices, you can maximize the benefits of using activated carbon.

Watermart is committed to assisting you in every step of selecting and implementing a water treatment solution with activated carbon. We provide high-quality products backed by knowledge and superior customer service, ensuring that you can achieve your water treatment goals with success and efficiency.

We hope this guide provides useful insight in selecting the right activated carbon for your water treatment system. By choosing the right solution, you not only ensure better water quality but also contribute to the health and well-being of the surrounding environment.

Contact us via Whatsapp or e-mail for your customized activated carbon needs, Watermart is ready to be your partner in achieving this goal, providing clean and healthy water for all.

.png?width=50&height=50&name=Logo_Watermart_Perkasa-removebg-preview%20(1).png)

-1.png?width=352&name=Karbon%20aktif%20adalah%20material%20yang%20sangat%20penting%20dalam%20berbagai%20industri%2c%20terutama%20untuk%20pemurnian%20dan%20filtrasi%20air%2c%20udara%2c%20dan%20bahan%20kimia.%20Dua%20jenis%20karbon%20aktif%20yang%20paling%20umum%20digunakan%20adala%20(1)-1.png)